Shell Turbo Turbine Oils

Turbine oils developed to protect, designed to perform

Often the unsung hero of power generation, your turbines are what helps drive the gears of industry forward – whether they’re used to maintain manufacturing chains or ensure an efficient energy supply.

Keeping the power flowing can be easier said than done, however, particularly amid the hostile operating environments that are common in these energy intensive industries. Environments that expose critical components to everything from high temperatures to heavy loads.

Fortunately, the right turbine oil can help. By prioritising protection and performance, our Shell Turbo range of turbine oils can help keep your equipment working exactly as it was designed. And with decades of success in the field, you can be sure that the Shell Turbo portfolio is made up of only the highest performing oils.

Key Benefits¹

Enhanced wear protection

The anti-wear performance of Shell Turbo oils helps reduce the risk of turbine failure, even for heavily-loaded gearboxes.

Extended oil life

Because unplanned downtime has never been more expensive, Shell Turbo oils deliver exceptional oil life under continuous operation.

Excellent system efficiency

Rapid air release combines with excellent filterability to help you get the most from your turbines, time after time.

High-temperature, fire-resistant performance

Overcome increased operating temperatures and fire hazards with an oil that not only survives, but thrives, amid thermal stresses.

Heavy-load protection

Excellent load-carrying capacity means reliable performance, even under severe, peak-load operation or cyclic peak-loading conditions.

Deposit and corrosion protection

Overcome increased operating temperatures and fire hazards with an oil that not only survives, but thrives, amid thermal stresses.

Turbine oils and GTL technology

Our gas-to-liquids (GTL) technology turns natural gas into high-performing liquid products. Using base oils derived from natural gas means fluids like our Shell Turbo range can offer various benefits over traditional group II/III base oils:

- A lower sulphur content than fluids derived from crude oil

- A more uniform chemical structure, contributing to reliable performance

- Neither crude oil nor location-dependent, meaning long-term availability is secured

And the differences don’t stop there. From lower volatility to a better additive response, GTL-based oils are uniquely designed for the demanding conditions experienced by today’s modern turbines.

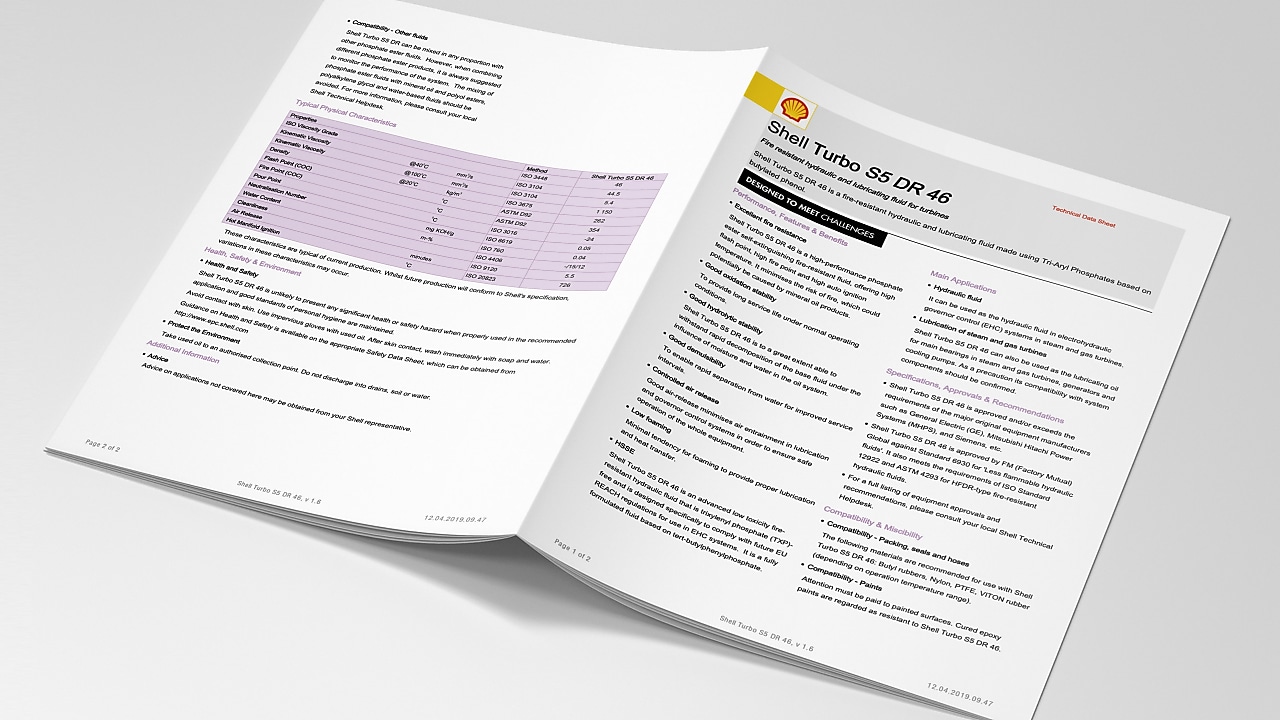

Shell Turbo product range

Prioritising wear protection, system efficiency and oil life, our Shell Turbo range of high-performance turbine oils has been developed to not only support protection, but improve performance. Find the right oil to meet your turbine’s needs across its entire lifetime.

Shell lubricants for turbines

Our wide-ranging portfolio of lubricants for turbines helps power companies and process plant operators keep their turbines operating at maximum capacity, with products made for everything from varnish removal to specialist applications.

Applications

From turbines to turbocompressors, the Shell Turbo range covers a number of specialist applications across industrial steam, light or heavy-duty gas, and combined-cycle systems, including those with specific needs relating to:

- High temperatures

- Enclosed gears

- Long life

- Flame resistance

- Load capacity

- High ammonia inertness

Real-world case studies

Kaplan case study

With no oil-related failures across 17 years of use, see how Shell Turbo Oil T 68 helped this hydroelectric power plant extend its oil life by 150%.

Toshiba case study

Discover how, as part of a holistic package of products and support, Shell Turbo Oil T 32 delivered a 20-year service life for this mining company’s turbines.

Voith Kapplan S case study

Learn how, thanks to reductions in downtime, maintenance and oil cost, Shell Turbo Oil T 68 and Shell LubeAnalyst helped this company save $69,000 annually.

IHI case study

Not only did Shell Turbo Oil T 46 help this state-of-the-art automotive production line increase oil-drain intervals by 33%, but it also reduced unplanned compressor shutdowns to zero.

Disclaimers:

1For more information around performance characteristics, test results and technical claims, please consult our Shell Turbo product brochure here: https://www.shell.co.uk/business-customers/lubricants-for-business/lubricants-product-range/shell-turbo-turbine-oils/download-the-shell-turbo-brochure.html

All data is derived from tests in laboratories of Shell Lubricant Solutions or partners using accepted standard methods.

For more product specific information, please visit www.epc.shell.com for more details.